Choosing the Right Aluminium Winding Wire Manufacturer in India: A Complete Industry Guide

In India’s fast-growing electrical and power distribution landscape, selecting the right aluminium winding wire manufacturers India is crucial for performance, safety, and long-term value. With an increasing shift toward lightweight and energy-efficient materials, aluminium winding wires have become a preferred choice across transformers, motors, home appliances, and more.

Whether you're an OEM, EPC contractor, or an industrial buyer, the right manufacturer can significantly impact your supply chain efficiency, product quality, and end-user satisfaction.

Understanding Aluminium Winding Wires: Why They Matter

Aluminium winding wires are used in place of traditional copper wires for their excellent conductivity-to-weight ratio, cost-efficiency, and easy availability. Their performance in electrical conductivity,mechanical strength, and thermal resistance makes them an industry favorite in the Indian market.

That’s why partnering with reputable aluminium winding wire manufacturers India is more than a procurement decision — it’s a strategic investment in your production quality.

Key Qualities to Look for in Aluminium Winding Wire Manufacturers India

When evaluating suppliers, it’s essential to assess them on the following critical parameters:

- Quality Standards and Certifications

Look for manufacturers who follow IS 13730 / IEC 60317 and have ISO 9001:2015 certification. High-quality aluminium winding wire manufacturers India will ensure wires have uniform insulation, smooth finish, and adherence to conductivity norms.

- Raw Material Quality

Pure EC grade aluminium is the baseline. Confirm whether your supplier uses virgin aluminium and maintains a consistent supply chain for raw inputs.

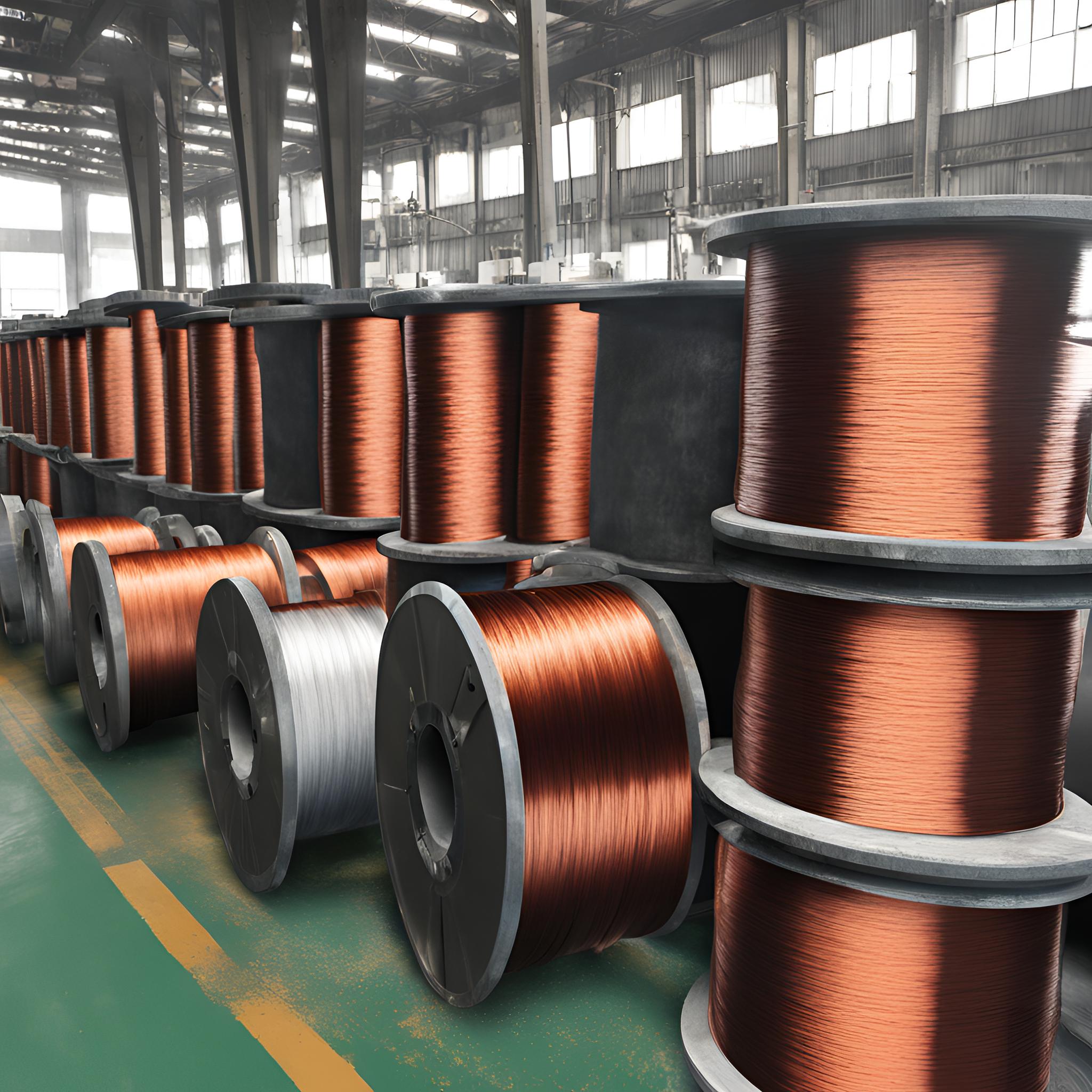

- Manufacturing Infrastructure

Advanced drawing machines, online enamel coating lines, and in-house labs for quality testing indicate serious manufacturing capabilities. Leading aluminium winding wire manufacturers India offer precision-engineered wires with tight dimensional tolerances.

- Customization Options

Your industrial needs might require variations in diameter, thermal class (155°C, 180°C), or insulation material. Only seasoned manufacturers will offer such flexibility without compromising on delivery timelines.

- Production Capacity and Lead Time

Check the monthly tonnage they can produce and how reliably they can meet your recurring demands. Timely delivery ensures your production schedules remain unaffected.

- Pricing Transparency

Competitive pricing matters — but not at the cost of quality. The best aluminium winding wire manufacturers India strike a balance between cost, quality, and service.

Why India Prefers Aluminium Over Copper for Winding Applications

With the rise in copper prices globally, India’s industrial users are shifting to aluminium as a cost-effective and performance-reliable alternative. The light weight of aluminium winding wires also reduces transport and installation costs, making them a suitable choice for high-volume usage.

Top aluminium winding wire manufacturers India are investing in R&D and automation to meet this growing demand.

Vidyametal: Trusted Among Aluminium Winding Wire Manufacturers India

At Vidyametal, we pride ourselves on being a top-tier supplier in the category of aluminium winding wire manufacturers India. With a strong presence across Gujarat and partnerships across the nation, we deliver:

- Wires from 0.2 mm to 4 mm diameter

- Thermal class wires (Class B, F, and H)

- 100% tested for dielectric strength, elongation, and pinhole

- Tailored packing solutions for domestic and export markets

Our reputation is built on quality, consistency, and customer-first service.

Market Trends: What Buyers Should Expect in 2025 and Beyond

According to IEEMA, India’s electrical industry is expected to grow at 12% CAGR, creating more demand for winding wire materials. Local aluminium winding wire manufacturers India are gearing up for this boom by upgrading their facilities and ensuring compliance with international standards.

Government support under schemes like “Make in India” further boosts the credibility of Indian manufacturers on the global stage.

How to Verify a Manufacturer's Credibility

Before placing a bulk order, make sure to:

- Ask for technical data sheets and test certificates

- Visit their plant (if possible)

- Check their client portfolio and service record

- Evaluate after-sales support and documentation process

Long-term reliability should always take precedence over short-term cost savings.

Sustainability and aluminium winding Wire Manufacturers India

Sustainability-conscious businesses are increasingly choosing aluminium due to its recyclability and lower environmental footprint compared to copper. Leading aluminium winding wire manufacturers India are aligning their operations with ESG goals by reducing scrap, energy usage, and water consumption in manufacturing.